Spiral Submerged Arc Welded (SSAW) Steel Pipe

As a professional spiral submerged-arc welded steel pipe manufacturer in China, Cangzhou spiral steel pipe company is capable of manufacturing double face submerged-arc welded spiral steel pipe with outside diameter in range from 219mm to 3500mm (8.62″-138″) for the clients in long distance transmission of natural gas, oil, chemicals, water, power, thermal power, and ocean dredging, etc. Our spiral welded pipe products comply with various international standards such as API 5L, ASTM, DNV, ISO, DIN, EN, BS, CE, CSA, etc.

| API | ASTM | BS | DIN | GB/T | JIS | ISO | YB | SY/T | DNV |

| 5CT | A53 | 1387 | 1626 | 3091 | 3442 | 559 | 4028 | 5037 | OS-F101 |

| 5L | A120 | 10219 | 9711.1 | 3444 | 3181.1 | 5040 | |||

| A135 | 9711.2 | 3452 | 3183.2 | ||||||

| A252 | 14291 | 3454 | |||||||

| A500 | 13793 | 3466 | |||||||

| A589 |

Technical Data

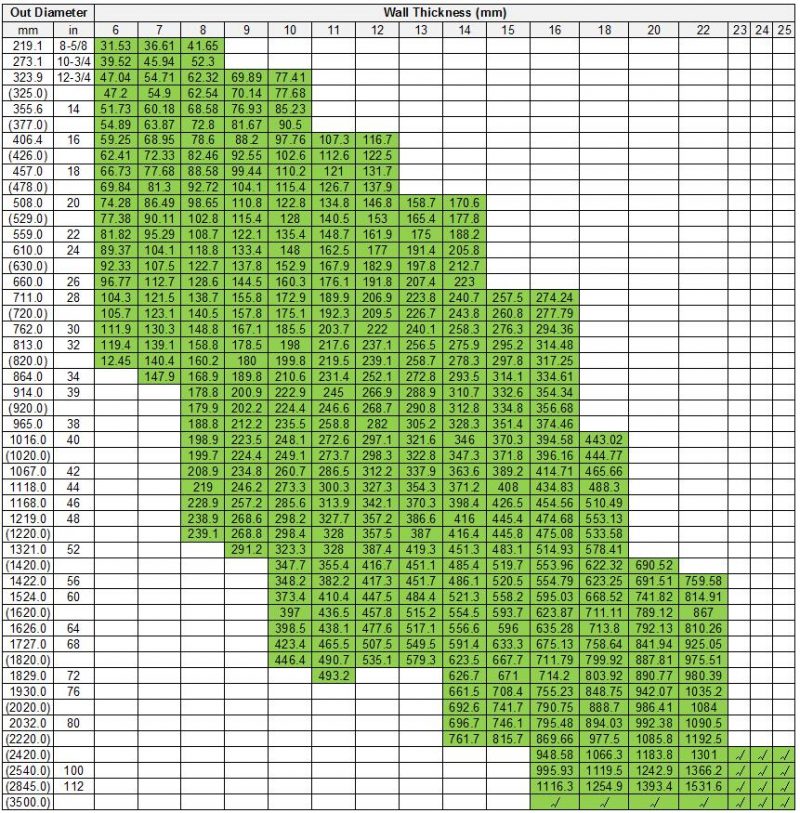

Outside Diameter (OD): Φ219mm – Φ3500mm (8.62″-138″)

Wall Thickness: 6.4 – 25.4mm (1/4″-1″)

Applicable Standards: API 5L (PSL1, PSL2), API 5CT PSL1, ISO 11960 PSL1, DNV, ISO, DEP, EN, ASTM, DIN, BS, JIS, GB, CSA, etc.

Length: 6-130m (20′-427′)

Grades: API 5L A-X80, GB/T 9711 L190-L625, GB/T 3091 Q215-Q345, ASTM A 53 Gr. A – D, ASTM A252 Gr. 1 – 3, EN 10217 P195TR1 – P265TR2, BS 1387/EN10219 S185 – S355, St12 – ST52

Coating services of SSAW steel pipe: single/double layer fusion-bond epoxy (FBE), two layers polyethylene/polypropylene (2LPE/2LPP), three layers polyethylene/polypropylene (3LPE/3LPP), polyurethane, concrete weight coating (CWC), insulation and bitumen external coating steel pipe and liquid epoxy, bitumen and cement internal coating steel pipe in accordance with international coating standards.

What is spiral steel pipe?

Spiral steel pipe, also known as spiral pipe or spiral welded pipe or spiral submerged arc welded (SSAW) steel pipe or submerged arc welded helical (SAWH) steel pipe, is a spiral seam steel pipe which is made of strip steel coil as raw material, extruded at normal atmospheric temperature and welded by automatic double-wire and double-sided submerged arc welding process. The spiral welded pipe production line sends the strip steel into the welded pipe mill, after rolling by multiple rollers, the strip steel is gradually rolled up to form a round pipe blank with an opening gap, the reduction of the extrusion roller is adjusted so that the weld gap is controlled at 1-3mm and both ends of the joint are flush.

Main features of manufacturing process

During the forming process of spiral submerged arc welded (SSAW) steel pipe, the deformation of steel plate is uniform, the residual stress is small, and the surface is not scratched. The processed spiral pipe has greater flexibility in the size specification range of diameter and wall thickness, especially in the production of high-grade thick-walled pipe, especially in the medium and small-diameter thick-walled pipe, which has incomparable advantages over other processes, and can meet more requirements of users in the specification of spiral steel pipe.

Advanced double-sided submerged arc welding technology can realize welding at the best position, and it is not easy to have defects such as misalignment, welding deviation and incomplete penetration, and it is easy to control welding quality.

Qualiry Assurance

100% quality inspection is carried out on the steel pipe, so that the whole process of steel pipe production is under effective inspection and monitoring, and the product quality is effectively guaranteed.

All equipment in the whole production line has the function of networking with computer data acquisition system, which can realize real-time data transmission, and the technical parameters in the production process can be checked by the central control room.

Raw material

Q235A, Q235B, 10#, 20#, Q345(16Mn), L245(B), L290(X42), L320(X46), L360(X52), L390(X56), L415(X60), L450(X65), L485(X70), L555(X80), L290NB/MB(X42N/M), L360NB/MB(X52N/M), L390NB/MB(X56N/M), 415NB/MB(X60N/M), L450MB(X65), L485MB(X70), L555MB(X80)

Grade

The rating standards for the spiral welded pipe include PSL 1 type and PSL 2 type as per API 5L standard.

Main uses of spiral submerged-arc welded (SSAW) steel pipe

Spiral welded steel pipes are mainly used in petroleum oil, natural gas, petrochemical, chemical, power generation plant, heat supply transmission, public waterworks, agricultural irrigation, urban construction and so on.

- Used for liquid transportation: water supply and drainage, petroleum oil & natural gas transportation.

- Used for gas transportation: coal gas, steam and liquefied petroleum gas, etc.

- Used as structure: used as steel pipe piling, bridge or structure pipes for docks, roads and building, etc.

Packaging for logistics of spiral steel pipe

Plastic caps in both end PVC sleeve.

Outer Diameter and Wall Thickness of SSAW Steel Pipe