Black 3LPE/3PE Anti-corrosion Coating Spiral Steel Pipe

Cangzhou spiral steel pipes company manufacture 219mm to 3500mm double face submerged arc welding SSAW SAWH spiral steel pipe in 6-25.4mm wall thickness with three PE layer (3LPE/3PE) or two PE layer (2LPE/2PE) in conformity with API, DNV, ISO, DEP, EN, ASTM, DIN, BS, JIS, GB, CSA standards for external coating.

This 3LPE/3PE coating usually are used on the external anti- corrosion coating for the spiral steel pipe.

What is Black 3LPE/3PE Anti-corrosion Coating Spiral Steel Pipe?

3LPE/3PE means the steel pipe has three PE layers including:

The first layer is FBE coating layer (FBE>80μm);

The second layer is AD coating layer (170~250μm);

The third layer is PE coating layer(1.8~3.7mm)

Note: Mostly, the color of PE coating layer is black. However, the PE coating layer can also be blue or yellow color which depends on clients’ requirements.

2LPE/2PE means the steel pipeline only have two coating layers, i.e. the second and the third layer. So the first layer is AD coating layer while the second is PE coating layer.

Three material mixed together, combined firmly with the steel pipe and become excellent anti-corrosion coating, which can be used in 70°C degree environment.

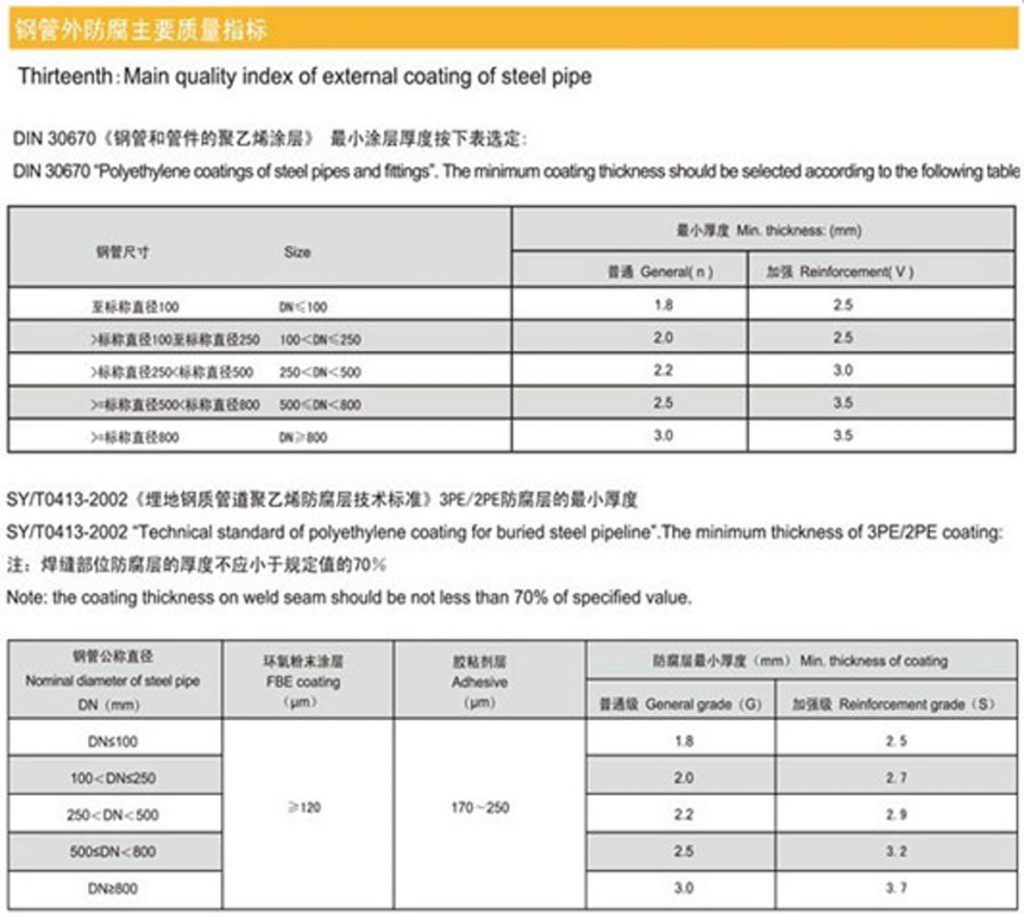

Applicable Standards: SY/T 0413-2002, GB/T 23257-2009, DIN 30670-1991, CAN/CSA Z245.21-2010, ISO 21809-1-2009, NF A49-711-1992, NF A49-710-1988, etc.

The min thickness of coating can refer to realted standards.

3LPE/3PE production process is as below: