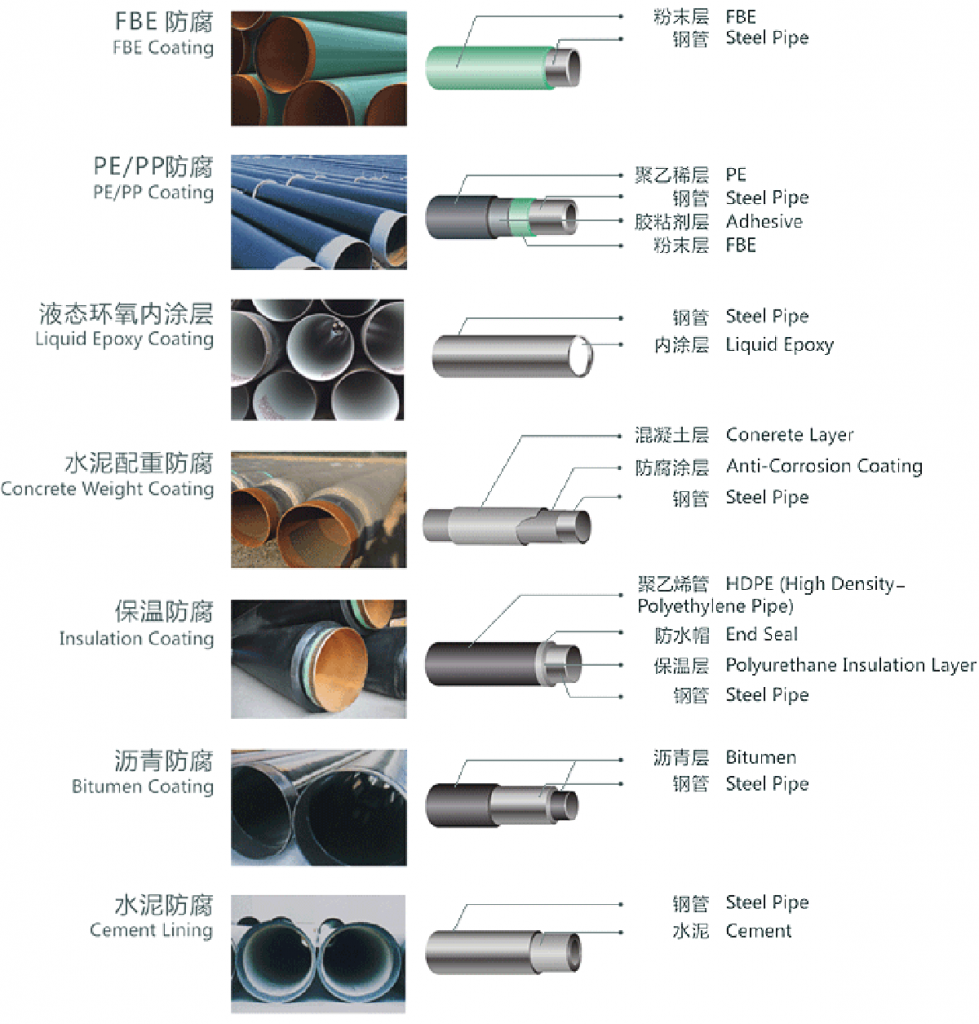

FBE 3PE 3PP Insulation Cement Lining Anti-corrosion Coating Spiral Steel Pipe

Cangzhou spiral steel pipes company manufacture 219mm to 3500mm double face submerged arc welding SSAW SAWH spiral steel pipe in 6-25.4mm wall thickness with FBE 3PE 3PP Insulation Cement Lining coating in conformity with API, DNV, ISO, DEP, EN, ASTM, DIN, BS, JIS, GB, CSA standards for internal and external coating.

Applicable Standards

- External Coating:

- SY/T 0315-2005, SY/T 0413-2002, SY/T 0415-1996

- GB/T 23257-2009, CJ/T 114-2000

- CAN/CSA Z245.20-2010, CAN/CSA Z245.21-2010

- DEP 31.40.30.32-Gen-2011

- ISO 21809-2-2007, ISO 21809-1-2009

- API RP 5L9-2001

- Q/enPC 38-2002, Q/HS 3017—2008, EN 253-1994

- DIN 30670-1991

- NF A49-711-1992, NF A49-710-1988

- BS 534-1990

- Internal Coating:

- API RP 5L2-2002, API RP 5L7-1988

- DEP 31.40.30.35-Gen-2005

- BS 534-1990

- AWWA C205-2000

More details about anti-corrosion coating Chinese standards and international standards can refer to Coating Standard for Anti-corrosion Steel Pipe.

The coating layers Include:

- GZ-2 Polymer Anti-corrosion Coating

- Single Epoxy Powder Anti-corrosion Coating

- Steel Lining FBE Anti-corrosion Coating

- Black 3PE Anticorrosion Anti-corrosion Coating

- Coal Tar Epoxy Anti-corrosion Coating

- Polypropylene 3PP Anti-corrosion Coating

- Blue 3PE Anticorrosion Anti-corrosion Coating

- IPN8710 Polymer Anti-corrosion Coating

- Double Epoxy Powder Anti-corrosion Coating

- Cement Mortar Lining Anti-corrosion Coating

- Polymer Anti-corrosion Coating

- Blue Epoxy Resin Outside Anti-corrosion Coating

- Preformed Directly Buried Polyurethane Insulating Anti-corrosion Coating

Anti-corrosion coating steel pipe refer to steel pipe which have been processed by anti-corrosion coating technology and can effectively prevent or slow down the corrosion phenomenon caused by chemical or electrochemical reactions during transportation and use.

At present, the annual corrosion loss of steel pipes in the world is as high as 500 billion US dollars. Anti-corrosion coating steel pipe can effectively prevent or slow down corrosion, prolong the service life of steel pipes and reduce the operation cost of steel pipes.

Anti-corrosion coating steel pipe are widely used in pipeline engineering fields such as long-distance water transmission, petroleum, chemicals, natural gas transmission, heat supply, sewage treatment, water, bridge, steel structure, marine water transmission, piling, etc.

Besides improving the service life of steel pipes through anti-corrosion coating, it is also showed as following:

- Combine the mechanical strength of steel pipes with the corrosion resistance of plastics;

- The external wall coating is more than 2.5mm, which is resistant to scratches and bumps;

- The friction coefficient of internal wall is small, 0.0081-0.091, which reduces energy consumption;

- The internal wall meets the national health standard;

- The internal wall is smooth and not easy to scale, and has self-cleaning function.